CUSTOMER:

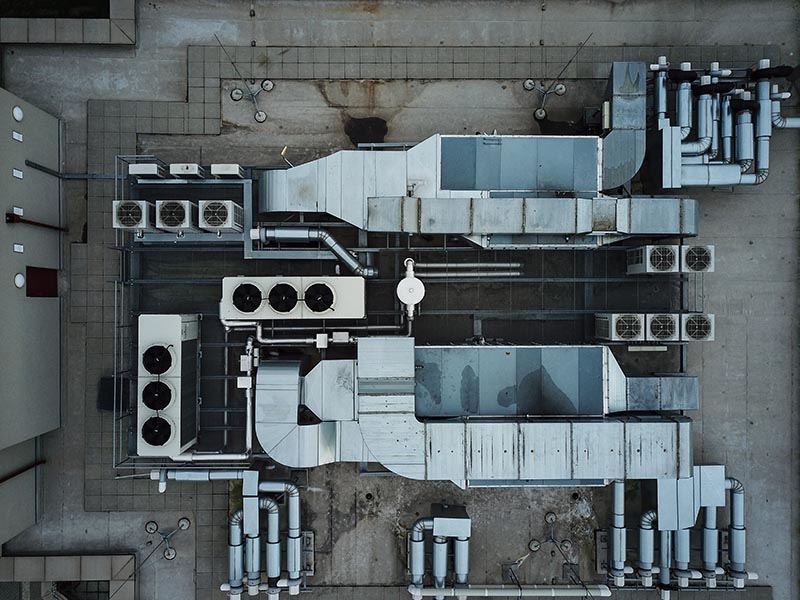

A global leader in the manufacture of air handling equipment.

Problem:

- Looking to provide their customers with a more robust air filter while maintaining air flow performance

- Avoiding a significant cost penalty

Structural Requirements

- An all-metal filter

- Had to be resistant to all types of weather conditions

- Capable of handling high amounts of air flow

- Able to remove large particulate

Airsan has been a leader in the design and manufacture of high performance metal filters since 1941. In this scenario, not only did we have to provide the OEM with a high-quality filter, but we needed to produce it within their budget.

Solution:

- The Airsan team, consisting of cross-functional representatives from production, engineering, and purchasing, collaborated to design and source the necessary media configuration and raw materials needed to deliver on the OEM’s specifications.

- We designed an all-aluminum filter, consisting of several unique layers of aluminum media that provided the structural rigidity and air flow performance desired by this customer. The new filter was successfully tested by the OEM, an independent lab, and ultimately certified by United Laboratories (UL900).

- As part of meeting the airflow requirements, Airsan applied a tackifier to help the particulate cake onto the filter.

- In order to be UL certified, this tackifier had to meet a certain flash point per the “Cleveland Open cup” test. Working with engineers who supply Airsan with the tackifier, we came up with a mixture that:

- Had enough viscosity to be propelled through a sprayer

- Would stick to the metal filter to help capture smaller particulate

- Meet the flash point needed by UL – per the “Cleveland open cup” test

- Once the testing and UL certification were completed and met the OEM’s requirements, Airsan moved to the pre-production trial runs and was ready to initiate first article inspection and begin the production ramp up.

- With the first filters coming off the production line, the OEM’s team of engineers were on site to validate the agreed upon tolerances and work with the Airsan production team to produce the first order of filters off the assembly lines.

Summary:

From initial discussion, design concept and first production run, Airsan was able to bring this new product to market in less than 6 months. This was truly a case of OEM and supplier working closely together to help deliver a new and enhanced product that provided:

- Enhanced value

- Without a cost penalty to the OEM

- View More Case Studies