FIlter:

Pre-Filter LM6000 GE Gas Turbine

Problem:

For several years, an end user and air filter manufacturer struggled to remove moisture from a gas turbine system.

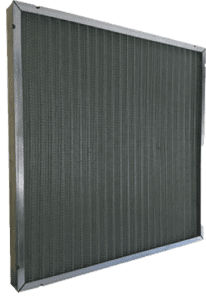

Initially, the air filter manufacturer installed traditional mist elimination filters consisting of a 3-layer metal filter. This configuration is similar to kitchen moisture and grease collection filters.

The initial design was the most economical solution, but it was soon discovered that the filter lacked the performance needed for the application. Whether it was the lack of moisture separation layers or the air velocity, the air filters were completely saturated after two months of service, reducing their performance and service life.

The end user came to Airsan looking for an alternative solution.

Solution:

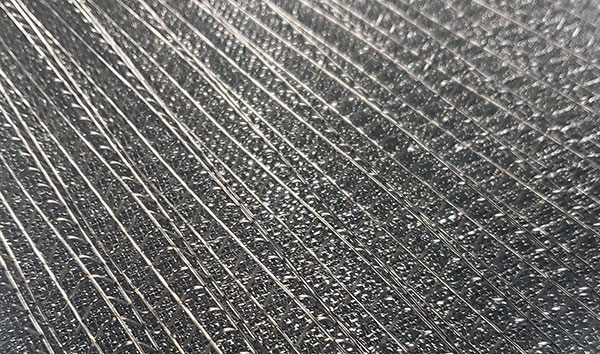

Airsan’s AFD filter was chosen for the application due to its design for moisture removal. Airsan’s AFD uses a unique progressive density design specifically developed to significantly reduce or eliminate moisture from the air stream. The progressive destiny is created using over 6+ layers of a specific media configuration.

To support Airsan’s claim of filter performance, the TYPE AFD was independently tested using the long-standing GE H2O Moisture Elimination Test Protocol. The results showed an impressive 99% H2O removal efficiency. These test results proved to the end user that the filter would not only eliminate moisture but that the media within the filter would not be compromised by an airflow more significant than 625 FPM.

Airsan was chosen for the project and is now beginning its 3rd year of service.

- View More Case Studies